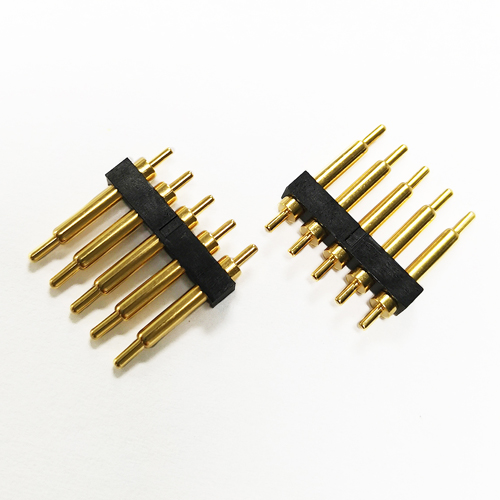

The needle and barrel of pogopin are usually made of brass, and copper is a very active metal material, so it will react with the oxygen in the air when exposed to the air, and its surface will be oxidized by the air. SopogopinThe pogo pins need to be electroplated on the surface, and it is more common to use gold plating on the surface.

The Pogopin material is mainly made of copper, and its surface is treated to make it corrosion-resistant and friction-resistant. The surface is then nickel-plated and then gold-plated and copper-plated and then tin-plated. Next, we will briefly analyze, Equipment, Pogopin treatment process and coating of the product to be plated. The Pogopin plating process is the same as the general plating process, but the working time of each process is significantly shorter than that of general plating. Therefore, each treatment solution and plating solution must be adjusted accordingly. Meet the requirements of short operating time.

pogopin gold plating process flow:

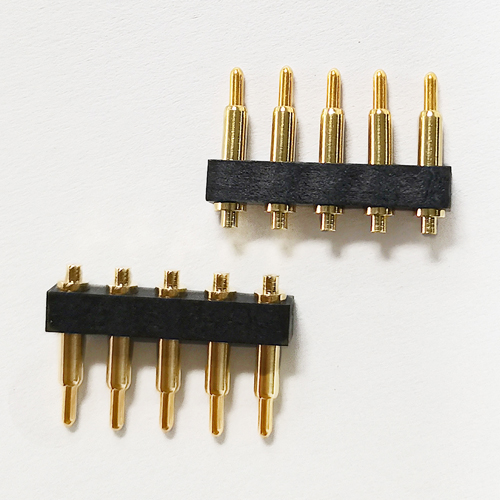

1 Degreasing: Different from the general electroplating process, the degreasing time of Bokoping is 25 seconds, so multi-stage electrolytic degreasing with high current density should be used.

2 Pickling: Due to the size requirements of the metal to be plated, Bokoping usually uses chemical grinding or electrochemical grinding instead of metal autolysis.

3 Nickel plating: Bokoping usually uses a sulfamate electroplating solution. The purpose of nickel plating is to provide a primer layer for gold plating, and tin plating to improve corrosion resistance and prevent the performance of the electroplating layer due to the substrate (mainly copper alloys). ) and the gold layer, or the interdiffusion between the lead layer is reduced.

The gold-plating process plays an important role in the electroplating process of pogopin connectors. Generally speaking, the thicker the gold-plated layer of the pogopin, the better the effect and the higher the unit price, so the thickness of the gold-plated layer is directly related to the cost of the pogopin.

The gold plating thickness of the commonly used pogoPin in the market is usually 3u'. At present, considering the cost, some users also use the gold plating thickness of 1u. In fact, there is no significant difference between 3u' and 1u' in terms of service life, compression reliability. Obviously The difference is that the salt spray and wear resistance of the gold-plated layer are better, and the needles of these two types of salt spray needles can pass 48 hours and 24 hours respectively.