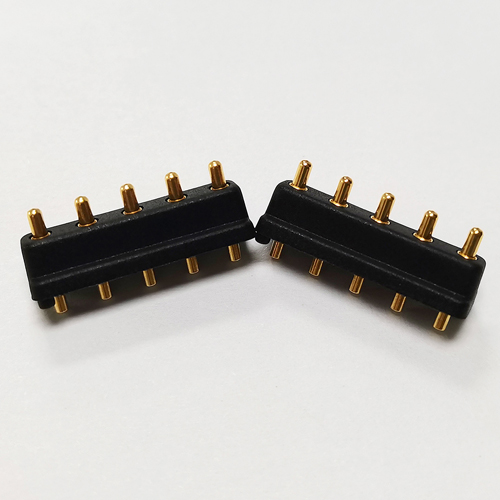

The pogopin pogo pin has stable dynamic impedance, low inductance, high current, long life, small size and strong customization; the use of the pogopin pogo pin can easily achieve waterproofing, and the pogopin pogo pin uses a special electroplating process to prevent sweat and contact.pogopin spring thimbleIt is a spring-type probe made by riveting and pre-pressing the three basic components of the needle shaft, spring and needle tube through precision instruments. There is a precise spring structure inside. The manufacturer of the pogopin spring thimble will make its surface gold-plated, which can better improve the Its anti-corrosion function, mechanical properties, electrical properties, etc.

At present, the working temperature of the pogopin pogo pin is 200 degrees Celsius, and the low temperature is -65 degrees Celsius. Since the current generates heat at the contact point when the pogopin spring thimble is working, it causes the temperature to rise. Therefore, it is generally believed that the working temperature should be equal to the sum of the ambient temperature and the temperature rise of the contact point. .In some specifications, the allowable temperature rise of the connector under the rated working current is clearly specified.

The pogopin pogo pin is characterized by short current path, smaller distributed capacitance and distributed inductance, and is more conducive to impedance matching in the high frequency range. Moreover, it can choose a variety of structures at will, and has a wide range of applications, including electronic equipment, smart home, Vehicles, communications, etc. Compared with traditional connectors, pogopin pogo pins can prevent electronic products from contacting water with simple design, resulting in machine equipment failure and short circuit.

The intrusion of moisture will affect the insulation performance of the pogopin spring thimble and corrode the metal parts. The constant humidity and heat test conditions are 90% 95% relative humidity, temperature plus 40 ± 20 degrees Celsius, and the test time is at least 96 hours according to the product specification. The damp heat test is more severe.

When the pogopin pogo pin works in an environment containing moisture and salt, its metal structure and contact surface treatment layer may cause galvanic corrosion, which affects the physical and electrical performance of the connector. In order to evaluate the ability of the electrical connector to withstand this environment , specifies the salt spray test. It is to hang the connector in the temperature-controlled test box, and spray the sodium chloride solution with the specified concentration with compressed air to form a salt spray atmosphere. The exposure time is specified by the product specification, at least 48 hours.

Pogopin pogo pins have a higher strength-to-weight ratio than any other shape. It is easy to machine with standard machine tools. It is easier to seal, insert and remove. High performance. Therefore, when multi-contact connectors are required to realize the interconnection between components and cables, cables and cables, pogopin waterproof connectors are the first choice.

The anti-vibration and anti-shock performance of pogopin spring thimble is an important performance of electrical connectors, especially in special application environments such as aerospace, railway and road transportation. An important indicator of reliability. There are clear regulations in related test methods. Shock test The peak acceleration, duration and shock pulse shape, and the time of interruption of electrical continuity shall be specified.